‘Build less’

Where possible, existing buildings and their facade systems should be refurbished rather than being replaced. Where facade systems cannot be re-furbished, their materials should be re-used or recycled for new facade elements, where this is viable. A new facade, installed on an existing building, may provide the opportunity to improve a building’s performance and reduce its operational energy, but this could also generate a significant amount of embodied carbon.

Stone taken from an existing facade could be re-used or re-purposed as the facing on new unitised facade panels. Insulating glass units could be reused or recycled into new architectural glass. Reusing existing materials not only helps to reduce a building’s UCE, it also helps preserve natural resources and biodiversity. Saint-Gobain Glass is currently the only glass manufacturer that operates a cullet return scheme in the UK, but others are expected to follow suit. A mechanism for taking advantage of the reduced UCE of recycled new glass remains to be developed.

‘Build light’

Building light involves engineering optimisation and more efficient facade design. This can lead to a reduction in the quantity of materials and a reduction in loads imposed on a primary frame. Optimising the architectural design of the facade by minimising or eradicating non-functional decorative elements and non-essential facing materials reduces the weight of a system, leading to a subsequent reduction in section and bracket sizes.

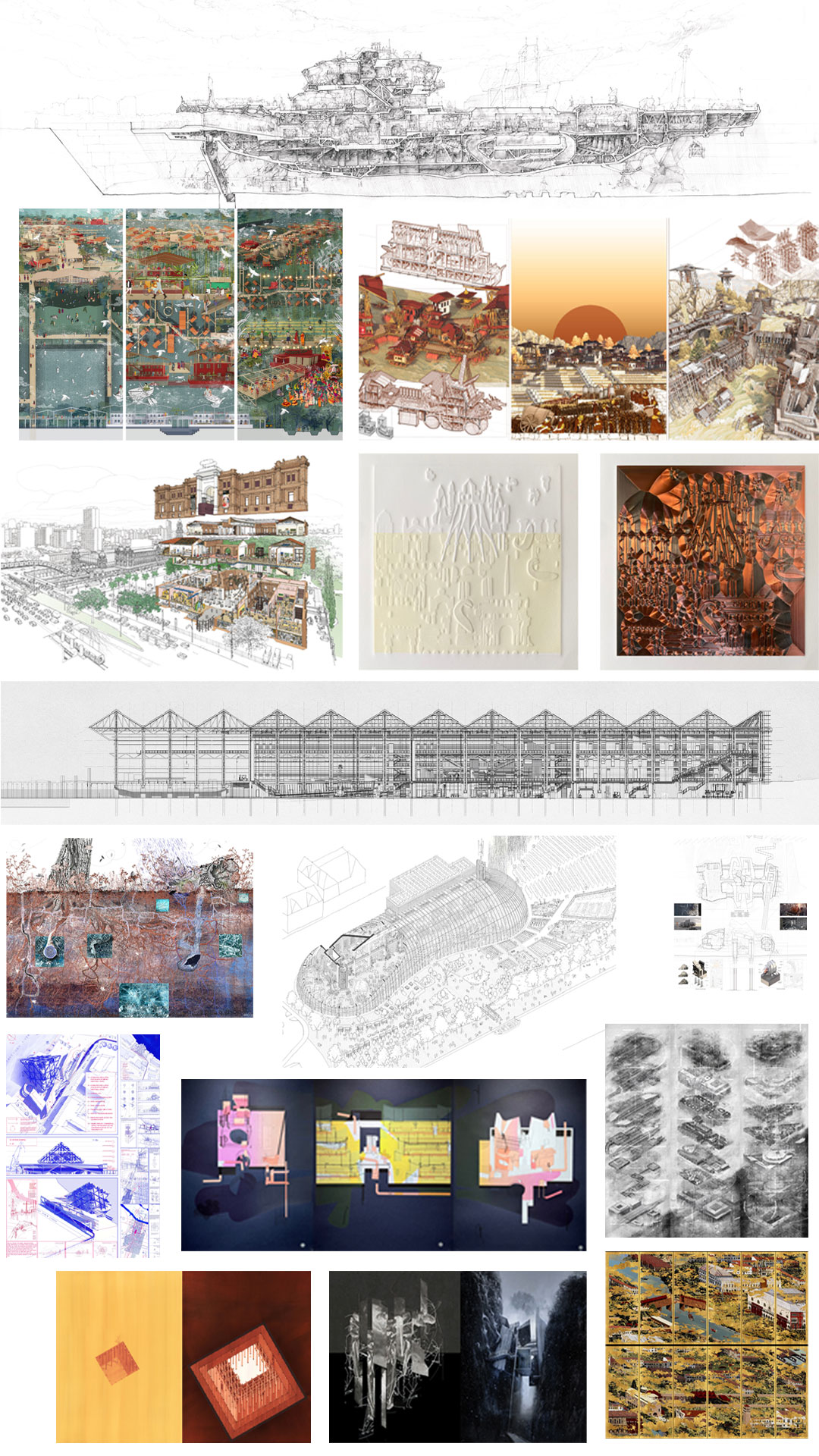

Ultra-High-Performance Concrete (‘UHPC’) panels may be used in place of traditional architectural precast concrete panels (Figure 2 below). While UHPC uses more cement than traditional precast, it is typically a third of the thickness of traditional precast, which results in a lower overall UCE. On top of this, the additional benefits of lighter UHPC panels are more efficient transportation to site and reduced loads on a primary frame. It should be noted that UHPC is best used with a facing material (e.g., brick, stone, terracotta), as the absence of aggregate in the mix means that the range of finishes is limited in comparison with traditional precast.

‘Build wise’

To build wise means to select durable cladding materials and finishes, and to consider their service life and maintenance/replacement cycles. Generally, cladding materials require regular cleaning, but minimal maintenance.

Insulating glass units (‘IGUs’) and associated gaskets and seals are typically replaced after 25 years. Increasing the longevity of IGU seals, and finding a way to re-fill cavities with Argon, will be a key challenge for the architectural glass industry.

The aluminium framing of a curtain walling system has a predicted service life of 50-60 years, which is equivalent to the design life on most buildings currently. However, this does not apply to polyester powder coated (‘PPC’) finishes, applied to the framing, that have a predicted service life of 25 years. It could be beneficial to specify an anodised finish, despite its higher UCE in comparison in PPC, as a result of its longer service life.

A further way to build wise is to minimise waste by designing systems that can be manufactured off-site (e.g., unitised curtain walling, large panel systems). These systems can achieve high recycling rates for any redundant materials.

‘Build low carbon’

Building low carbon, by specifying renewable or recycled materials from responsible sources, is another key action. Specific measures can be taken to reduce the upfront carbon emissions of aluminium, glass and concrete.

Aluminium is one of the most durable and versatile materials used in facade construction, in the form of extruded profiles and sheeting for curtain wall, windows and doors. However, it has one of the highest UCE per kg of any material.

It is possible to use ‘low carbon aluminium’ by specifying either primary aluminium ingots produced with renewable energy, or aluminium ingots with a high post-consumer recycled aluminium content. Even though primary aluminium, produced from CO2 free energy, is widely available from several aluminium producers and is used by various façade companies, the high recycled content ingots are only available from Hydro and mostly for their in-house façade systems. An important distinction between pre-consumer and post-consumer aluminium scrap should be made; the former being aluminium that has never been in service (e.g., from fabrication off-cuts) and the latter being aluminium that had a useful life in the form of windows, etc., and has been subsequently dismantled and recycled. Unfortunately, there is not enough post-consumer aluminium scrap available for recycling today, or capacity to sort it efficiently, which means that it accounts for only approximately 20% of the current total aluminium supply in Europe (the percentage is even lower in the construction industry). However, according to the European Aluminium Association, there is potential to achieve close to 50% of the total demand with post-consumer aluminium by 2050.

Glass is a unique material in that it is 100% recyclable, it is resistant to chemicals and has special aesthetic properties. Even though cullet (i.e., recycled glass) lowers the UCE of new glass, insulating glass units are not commonly recycled into new architectural glass, but rather downcycled. Nevertheless, there are steps that can be taken to reduce the UCE of insulating glass units, which do not involve recycling of existing glass. Generally, mid or reduced iron glass has a lower embodied carbon than full low-iron glass as the former has a higher percentage of cullet. Annealed glass has a lower embodied carbon than heat-treated glass, but a single monolithic toughened glass pane has a lower embodied carbon than a laminated annealed glass pane. A low-carbon glazing approach is one where glass build-ups have been carefully optimised by considering their UCE along with the other performance factors.

Precast concrete is typically used as a panelised facade system in 150mm thickness either fair faced or with various facing materials, and is preferred because of its high-quality finish, off-site manufacture, and speed of erection. Surprisingly, it also has a low UCE per m2 of facade, when compared to an aluminium curtain walling system. Cement replacement can have the biggest impact in reducing its UCE, as approximately 60% of the total UCE of a precast concrete facade panel comes from cement production. Up to 50% of the Portland cement can be practically replaced by Ground Granulated Blast-furnace Slag (‘GGBS’), a by-product of the steel industry. This can lead to a reduction of approximately 25% in the overall UCE. Other advantages of GGBS cement are its lighter colour, smoother texture, and a reduction in the occurrence of efflorescence. However, GGBS cement cures more slowly than Portland cement, which slows down the production process and increases the cost of manufacture. In higher concentrations, it also has a distinct blue hue, which is not ideal for architectural fair-faced concrete finishes. Finally, as there is a shortage of GGBS in the UK currently (Source: BEIS Research Paper No. 19), it is important to take the source of the GGBS into account.

‘Build for the future’

Designing flexible and adaptable façades that can be easily maintained and upgraded is the key when thinking about the future. The most common way to upgrade an existing curtain walling or window system is to replace the insulating glass units at the end of their service life with higher performing ones, providing the framing system remains in good condition. Replacement is easier to achieve, and results in lower carbon emissions, if dry glazed gasket systems are used rather than structurally glazed ones.

Building for the future also requires focussing on design-for-disassembly and circular economy principles for the end of life of the facade. The appropriate design of mechanical connections, specifying IGUs that are easier to reuse and recycle, and keeping a detailed record of all materials employed in the construction, can aid their future re-use and recyclability. More specifically IGUs are easier to recycle if the following are avoided: ceramic frits and prints, body-tinted glass, and laminated glass panes with thick interlayers (currently only laminated glass panes with a 0.76mm thick PVB interlayer can be recycled).

‘Build collaboratively’

The final step, but possibly the most important one, is to build collaboratively, by sharing knowledge between parties. This is crucial because the process of measuring, verifying and disclosing whole life carbon values is still in its infancy and is continuously evolving. Fruitful interdisciplinary collaboration and open book data are essential to build net-zero carbon buildings, and we all must help towards this goal.

- Figure 1 – LETI hierarchy for embodied carbon reduction, modified for facades by FMDC

- Figure 2 – UHPC panel with limestone facing (Source: Hofmann Facades)

- Figure 3 – European aluminium supply – 2019, 2030 and 2050 (Source: CRU, 2019, found in Circular Aluminium Action Plan by European Aluminium)

- Figure 4 – Upfront carbon emissions (A1-A3) of double-glazed units based on EPD from Saint-Gobain Glass