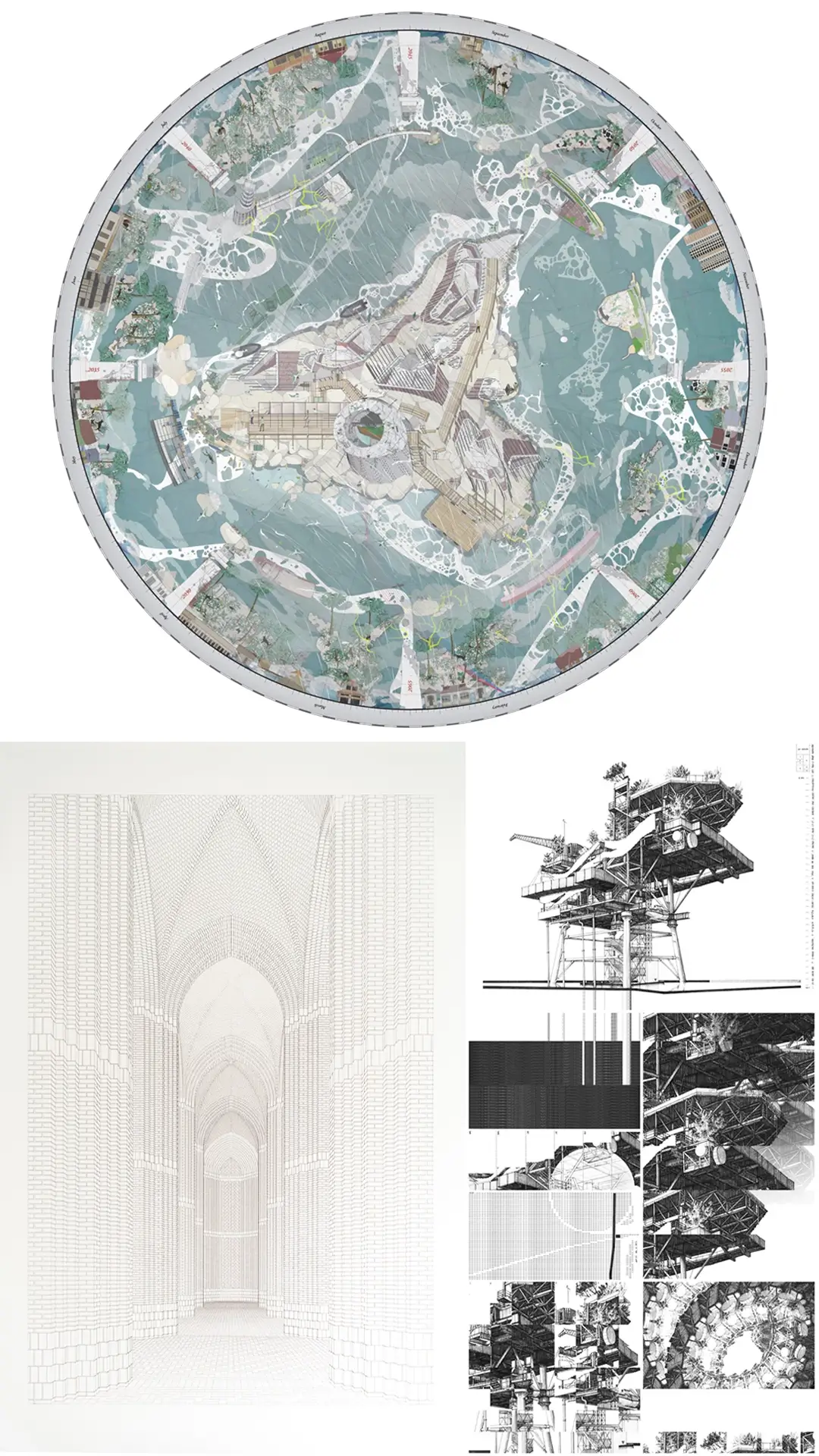

- Winner of The Architecture Drawing Prize 2023: an interview with Eldry John Infante

- Developing in the City: New Build vs Retrofit

- Transforming Cityscapes with the Power of Nature

- Making luxury circular: rethinking re-use in retail fit-outs

- Is it mean to cut down trees?

- “Drawing as a method of dialogical design” – an interview with Eugene Tan

- “I’m interested in intricate and intimate architecture that directly affects people.” – Samira

- Refresh, repurpose, reimagine: Our approach to retrofit

- Developing in the City: New Build vs Retrofit Part 2

- Make models: Carlisle Health and Wellbeing Centre

- AI integration at Make: shaping the future of architecture

- Optimising the value of build-to-rent

- Tall buildings photo essay

- Reflections on Make Neutral Day 2024: Part 2

- Is it green to cut down trees?

- Make models: Station Row section model

- Make models: Drum

- Make models: Milton Avenue/Station Row

- Reflections on Make Neutral Day 2024: Part 1

- Defining a sustainable workplace – the BCO’s climate emergency challenge

- Discussing exhibitions with Dr Erin McKellar, Assistant Curator (Exhibitions), Sir John Soane’s Museum

- “Spirit is pure, so that’s what I feel here.” – Aunty Margret

- Hydrogen: Solution or ‘Techcrastination’?

- Carbon goggles: looking for facades of the future by reflecting on facades of our past

- Winning the 2022 Architecture Drawing Prize

- Variety in urban living: setting the scene

- Make models: Salford Rise

- Variety in urban living: the challenges and opportunities

- Make models: Seymour Centre

- Wilding the City

- Make models: 20 and 22 Ropemaker Street gift models

- Variety in urban living: innovation is key

- Reflections on Make Neutral Day 2023: Part 1

- Designing Regenerative Travel

- Make models: Jersey South Hill

- World Heritage Day 2023 Photo Essay

- Reflections on Make Neutral Day 2023: Part 2

- “Let’s do something a bit different”

- A deep dive into an amazing ‘Wunderkammer’

- Make models: shopping centre competition facade

- “My first subject was a house. From then on, I started developing my drawing skills.”

- The Spirit of Mountain

- Make models: Brookfield Place Sydney

- Make models: community library model

- Q&A with Maker Michelle Evans, project lead on Capella Sydney

- Challenging structural conventions at 80 Charlotte Street

- The power of creativity and experimentation

- Hyperlocal retail post-Covid

- Architectural Drawing: From Soane’s Time to Today

- New business models for a different retail future

- Internet shopping and the effect on cities

- The value of outreach – reflecting on our school engagement with RIBA Architecture Ambassadors

- Pink light veggies

- “I’ve wanted to be an architect since I was four years old.”

- “I’m learning that architectural designs will need to work in the real world.”

- The town centre in five years’ time: Community [1/3]

- Make–ReMake

- Embodied carbon of transportation

- From listed buildings to 21st-century schools [2/2]

- Drawing Sydney

- Inspired by “art built” – an interview with Marc Brousse

- Embodied carbon in curtain walls

- Reducing embodied carbon isn’t all about materials

- “Tall buildings mesmerise me.”

- Make models: metal etching

- “I’m the first one in my family pursuing architecture.”

- “What can you see behind this building?” – an interview with Fe

- My next getaway

- The town centre in five years’ time: Wellbeing [2/3]

- Make models: 80 Charlotte Street

- Living Architecture: Urban Forest

- “I want to build things that will explore new depths of the sea.”

- Upfront carbon: how good is good enough?

- The town centre in five years’ time: For everyone [3/3]

- Winner of The Architecture Drawing Prize 2020 – an interview with Clement Laurencio

- Restoring Hornsey Town Hall’s clocks

- A Proposed Hierarchy for Embodied Carbon Reduction in Facades

- From listed buildings to 21st-century schools [1/2]

- Comparing embodied carbon in facade systems

- Building Natural Connections with Energy, People, Buildings

- Bridging the gap

- Designing in the wake of coronavirus

- Living employment

- Atlas – Tech City statement

- Four ways residential design might change after COVID-19

- Post COVID-19 – What’s next for higher education design?

- Inspiring Girls

- Stephen Wiltshire

- The future of retail and workplace

- Make models: The Cube

- International Women’s Day 2020

- Architectural Drawing: States of Becoming

- One Make

- Post-COVID

- The Architecture Drawing Prize exhibition reviewed

- ‘Architecture in the frame’ – London Art Fair

- A Hong Kong perspective on a post COVID-19 society

- Chadstone Link: Making new connections

- Improving social ties in our cities

- Design narratives and community bonds

- Behind the scenes at the 2019 World Architecture Festival

- Drawing on the culture that makes the buildings

- Future modelmakers 2020

- The City is Yours

- After coronavirus, how can we accelerate change in workplace design to improve connection and wellbeing?

- The Madison model by Theodore Polwarth

- Q&A with our student modelmakers: Theodore Polwarth

- The Teaching and Learning Building model by James Picot

- Q&A with our student modelmakers: James Picot

- Pablo Bronstein

- The Big Data Institute model by Finlay Whitfield

- Q&A with our student modelmakers: Finlay Whitfield

- Encouraging spaces of conviviality

- The importance and passion of heritage in the built environment

- No show, so what next?

- Choosing architectural modelmaking

- World Heritage Day 2020

- Make models: Agora Budapest

- Drawing in Architecture

- Draw in order to see

- Project delivery at 80 Charlotte Street

- Our commitment to sustainable design

- Asta House – Local living in Fitzrovia

- Make models: Chadstone Link

- Transparency and a sense of investment

- Langlands and Bell – Observing and Observed

- Telling Stories: The power of drawing to change our cities

- Musings on The Architecture Drawing Prize 2020

- What role will hotels play in our society after COVID?

- Sketchbooks: draw like nobody’s watching

- Honest, in-depth learning

- Museum for Architectural Drawing, Berlin

- Make models: 20 Ropemaker Street, part 2

- The value of the drawing

- The hand does not draw superfluous things

- Balance

- Prized hand-drawings return a building to an organically conceived whole

- Draw to Make

- Drawing details – technical and poetic

- Betts Project

- Living with loneliness

- Combating loneliness in the built environment

- An update from Sydney

- Retail innovation beyond the shop door: Lessons from the USA (part 1)

- Make models: 20 Ropemaker Street, part 3

- Sydney born and razed

- Retail innovation beyond the shop door: Lessons from the USA (part 2)

- Make models: 20 Ropemaker Street, part 1

- Retail innovation beyond the shop door: Lessons from the USA (part 3)

- Architecture and Creativity

- High-density living in Hong Kong

- Make’s past, present and future

- The Architecture Drawing Prize – Not just another competition

- Leaving a mark

- Community connections

- My time with the BCO

- The call of the wild

- The art of an art historian

- Mary, queen of hotels

- Make models: Portsoken Pavilion

- The Make Charter

- Why Brexit will see a glass half-full emptied

- Make models: LSQ London

- Disappearing Here – On perspective and other kinds of space

- Drawing and thinking

- Drawing to an end?

- Making shops exciting again: Lessons from the Nordics (part 1)

- Make models: Grosvenor Waterside

- Drawing architecture

- The Hollow Man: poetry of drawing

- Above and beyond

- Making shops exciting again: Lessons from the Nordics (part 2)

- Plein air in the digital age

- A “Plan in Impossible Perspective”

- Art Editor’s picks

- Making shops exciting again: Lessons from the Nordics (part 3)

- The future of bespoke HQs

- Make models: The Luna

- World-class architecture

- The Architecture Drawing Prize exhibition review

- The future is bright but not the same

- Employee ownership

- The tools of drawing

- Trecento re-enactment

- Lessons on future office design from Asia Pacific

- The human office

- How drawing made architecture

- Advocating sustainable facade design

- Make models: FC Barcelona’s Nou Palau Blaugrana

- Drawing as an architect’s tool

- Are you VReady?

- Cycle design for the workplace

- The Architecture Drawing Prize

- Make models: an urban rail station

- Reporting from Berlin

- City-making and Sadiq

- Hand-drawing, the digital (and the archive)

- Ken Shuttleworth on drawing

- The green tiger

- Stefan Davidovici – green Mars architect

- When drawing becomes architecture

- Make models: Swindon Museum and Art Gallery

- The role of the concept sketch

- Make calls for a cultural shift in industry’s approach to fire safety

- 2036: A floor space odyssey

- Harold on tour

- London refocused

- Hotels by Make

- Full court press

- Digital Danube

- Don’t take a pop at POPS

- The future of architecture – Matthew Bugg

- The future of architecture – Jet Chu

- The future of architecture – Robert Lunn

- The future of architecture – David Patterson

- The future of architecture – Rebecca Woffenden

- The future of architecture – Katy Ghahremani

- Safer streets for all

- The importance of post-occupancy evaluation for our future built environment

- Put a lid on it

- Designing for a liveable city

- The future of architecture – Bill Webb

- Bricks – not just for house builders

- Designing in the City of Westminster

- Rolled gold

- How to make a fine suit

- Responsible sourcing starts with design

- Is off-site manufacture the answer?

- Developing a design for the facade of 7-10 Hanover Square

- Curious Sir Christopher Wren

- Responsible resourcing should be an integral part of every project

- The socio-economic value of people-focused cities

Model-making is central to our design process at Make. 3D-printed models in particular – from individual detail components to site models and 1:1 cladding mock-ups – form the bulk of the models we create. In 2019 our in-house modelshop printed thousands of models on our 14 Ultimaker printers, using nearly 500kg of filament.

How do we use that much filament while striving to be as sustainable as possible? It’s simple. All our filament is PLA, a plant-based bioplastic with a fraction of the carbon footprint of traditional plastics. Plus, the PLA we use – from sustainable 3D printing business Filamentive – is made from factory waste streams rather than virgin pellets, which goes even further to conserve natural resources. They’ve also recently shifted to using cardboard, instead of plastic, reels for their filament.

But we want to do more, so we’ve just invested in a SHR3D IT Recycler, Airid Polymer Dryer and Precision Filament Maker from 3devo. These machines allow us to recycle our 3D prints into new PLA filament for further printing and recycling – a fully closed-loop production process in the comfort of our London studio.

The process is straightforward. Once a print is no longer needed, we shred it. The resulting granulate is moved to the dryer, since polymers often have excess moisture. After that, the dried granulate goes into the filament maker, which can reach temperatures of 450C, for melting and forming new filament.

We’re excited about the potential of this technology, since PLA can be recycled more than once. The machines have the capacity to easily recycle all of our old 3D printed models. We’re currently still in testing mode, but our aim for 2021 is to close the loop and reduce our need for new filament.