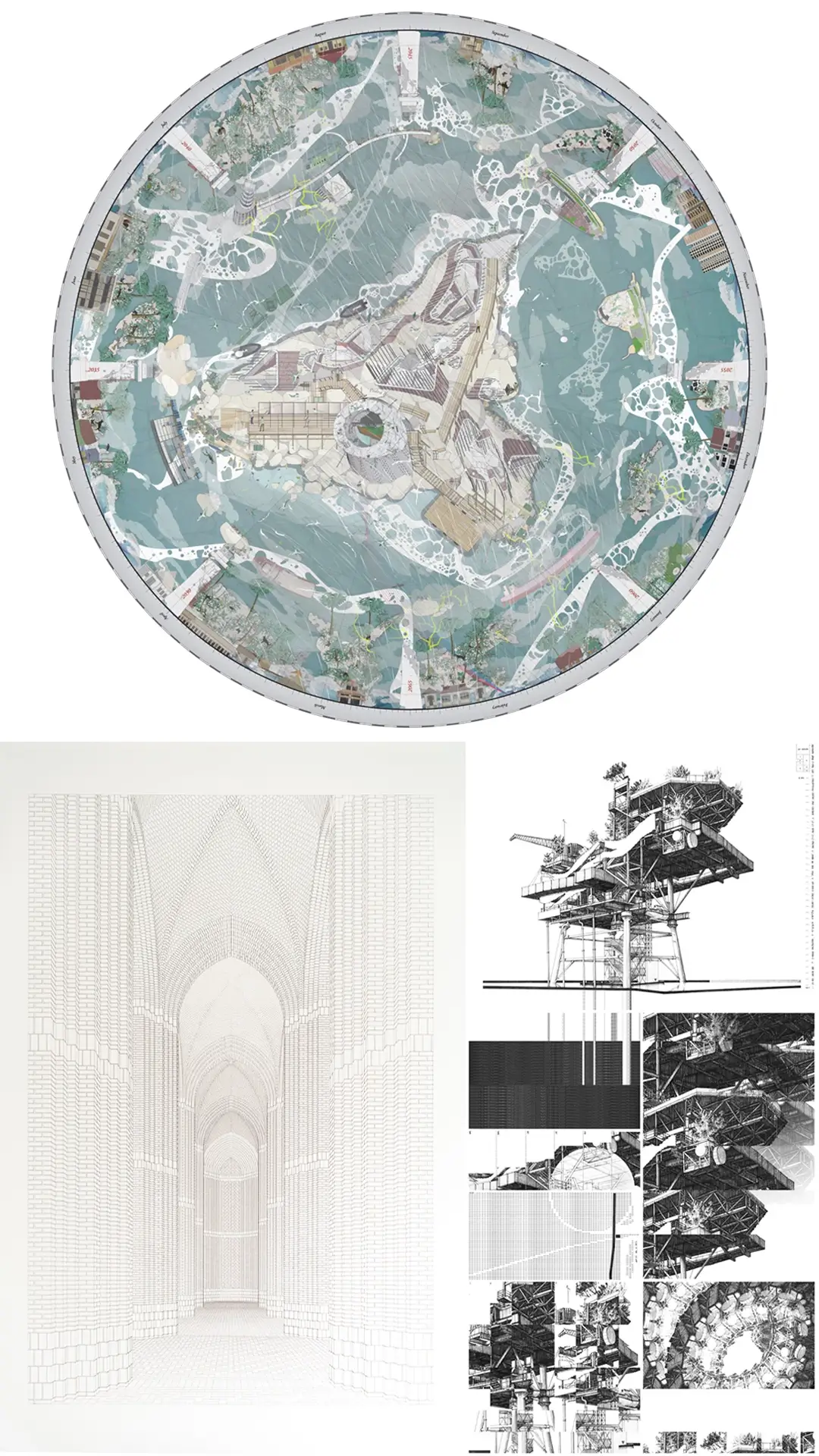

Form factor

If the case is made for a new build, then the massing of the building is one of the biggest factors in determining its embodied carbon. ‘Form factor’, the ratio of heat loss envelope (ground, walls and roof) to heated floor space is often discussed in terms of minimising operational carbon but it makes a huge difference to embodied carbon as well. The simplicity and efficiency of a building’s form is key, as increasing complexity almost always increases embodied carbon. Each recessed entrance, cantilever, inset balcony and facade step comes at a carbon cost and we designers must be rigorous in using these only when essential. Of course, our designs must always respond to context and scale, and must always provide great daylight, ventilation, and outdoor spaces for occupants’ wellbeing, but we must do this in the most efficient way possible to reduce embodied carbon. Helpfully, this is a win-win situation, where the most compact and efficient design is also usually the lowest cost.

These examples show how the same sized office building on the same sized site can have a very different form factor and wall-to-floor ratio according to its shape. The carbon footprint of the facade construction will vary greatly depending on how much facade is needed to enclose the same floor area.

Structural efficiency

The largest portion of embodied carbon in a new building is in the structure and substructure.

Structural engineers are successfully leading the conversation on reducing embodied carbon through reuse, minimising basements, smaller and more efficient building grids, and questioning loading criteria. Andrew Wylie of Buro Happold gave a great 10 minute presentation of their structural sensitivity study at the Architects Declare Workshop on Embodied Carbon in March 2020.

As architects, we must prioritise structural efficiency in our earliest concept sketches, often before the engineers are appointed. The buildings we build now must be ‘long life, loose fit’ to ensure they can be adapted to future needs. Smaller building grids usually reduce upfront embodied carbon but are sometimes resisted as being less adaptable. In fact, the most common reason for not being able to reuse an existing structural frame is that the floor-to-floor height is too small, not that there are too many columns. With an extra few hundred millimetres on the storey height, a building is much more adaptable and future-proofed to new servicing strategies or local structural changes. We believe that embodied carbon is often better spent on storey height, giving better daylighting and ventilation options, than in a wider column spacing. On one of our larger workplace schemes, we have developed an innovative ‘tree column’ to give smaller structural grid efficiencies while maintaining a wider column spacing. When minimising embodied carbon is a serious goal, innovative designs arise through collaboration.

Facade and structure

Structural efficiency doesn’t end with the building grid. The way the facade is supported or restrained by the primary structure can have a big impact on the structural embodied carbon and the way it’s made affects its aesthetic. So our first concept sketches can set constraints on the facade which affect the structure and we must be mindful of the impact on embodied carbon.

It’s not as simple as a heavy facade needing more structure than a light facade; often, limits on structural deflection are more critical. The diagrams below show four different ways that the facade can interface with the primary structure.

- A load-bearing facade can avoid a potential doubling up of a strong facade and the primary edge structure. This is a radical option which affects thermal lines and programme, particularly, but could result in big embodied carbon savings.

- A self-supporting facade carries its own weight down to the ground and takes restraint only from the primary structure. This is a good option for up to five or six storeys and can keep the primary structure very lean.

- Facades that can span between column positions load the primary structure only at its strongest points. Panelised facades, made off-site, can have a very efficient relationship to the primary structure.

- Facade systems which fix all along the primary edge structure, such as curtain walling, SFS or blockwork, will need those edge beams to be stiffened, increasing the embodied carbon of the structure. We can try to design for increased deflections, perhaps making wider joints part of our design aesthetic.

CLT panel used as a backing wall for the ceramic rainscreen at our Teaching and Learning Building for University of Nottingham. This loads the structural frame at the grid lines.

Using less

So we can talk about making big reductions in embodied carbon without talking about materials at all. Key design moves at the start of the project will make the biggest difference: reusing existing buildings where possible, keeping new building forms simple and efficient, ensuring structural efficiency, keeping structural grids small and considering how the facade interacts with the frame are key contributors to the overarching principle of using less. Then as the conversation moves to materials, we’ll have the best chance of meeting ambitious embodied carbon targets.